Just north of UT’s main campus sits the J.J. Pickle Research Campus—a sprawling 475-acre site dedicated to advancing research. It's also home to one of the most unique pilot plant facilities on any college campus in the United States, and where Texas ChE engineers collaborate with industry partners on ground-breaking research projects.

Originally a magnesium plant during World War II owned by the United States government, UT purchased the land that would become the J.J. Pickle Research Campus (PRC) in 1949. The property had many iterations before being renamed for Congressman and UT alum J. J. Pickle in 1994.

Numerous research centers and groups call the PRC home, many with strong ties to the McKetta Department of Chemical Engineering. Examples include the Center for Energy and Environmental Resources (CEER) which was directed for 25 years (1999-2024) by chemical engineering professor and Interim Department Chair David Allen.

The Texas Institute of Electronics grew out of the NSF-funded Nanomanufacturing Systems for Mobile Computing and Energy Technologies Center known as NASCENT, which was co-founded in 2016 by chemical engineering professor and current Cockrell School of Engineering Dean Roger Bonnecaze.

But arguably most unique at the PRC is the James R. Fair Process Science and Technology Center (PSTC), where academia and industry collaborate on real-world, ground-breaking research projects. There is no other pilot plant research facility like it anywhere else in the world.

PSTC Origins

To understand what the PSTC is today, one must go back a few decades. In the mid-80s, a new sector was emerging, fueled by the oil shocks of the 1970s. Prices had surged but government deregulations meant new opportunity for the new decade.

James R. Fair returned to UT as a professor in 1979, having earned his Ph.D. in chemical engineering in 1954 under Dr. Howard Rase, and after more than 3 decades at Shell and Monsanto Company. He was particularly interested in distillations and extractions.

In 1983, Fair, along with chemical engineering alumnus, Jimmy Humphrey, Ph.D. 1967, established the Separations Research Program (SRP), with a primary focus on mass-transfer and hydrodynamic characteristics of commercial-scale extraction and distillation devices, utilizing large and pilot-scale equipment for distillation, liquid extraction, and supercritical extraction. A consortium of industry and academia partnerships was built where fundamental research in chemical, biotechnological, petroleum refining, gas processing, pharmaceutical, and food companies took place. At one point it had as many as 40 industrial partners.

Fair, named a member of the National Academy of Engineering in 1974, also built a pilot plant for separations research projects. As the SRP continued to evolve, it was later renamed in honor of Fair for his significant contributions to the center and as a renown expert in distillation and process design.

PSTC AND INDUSTRY

The late Texas ChE alum Jose Bravo, M.S. 1981, served as the plant’s research program manager until 1991. While UT provided initial capital to establish the facility, Bravo's role led the charge to maintain and increase an income stream by offering state-of-the-art equipment and world-class research services for industry needs.

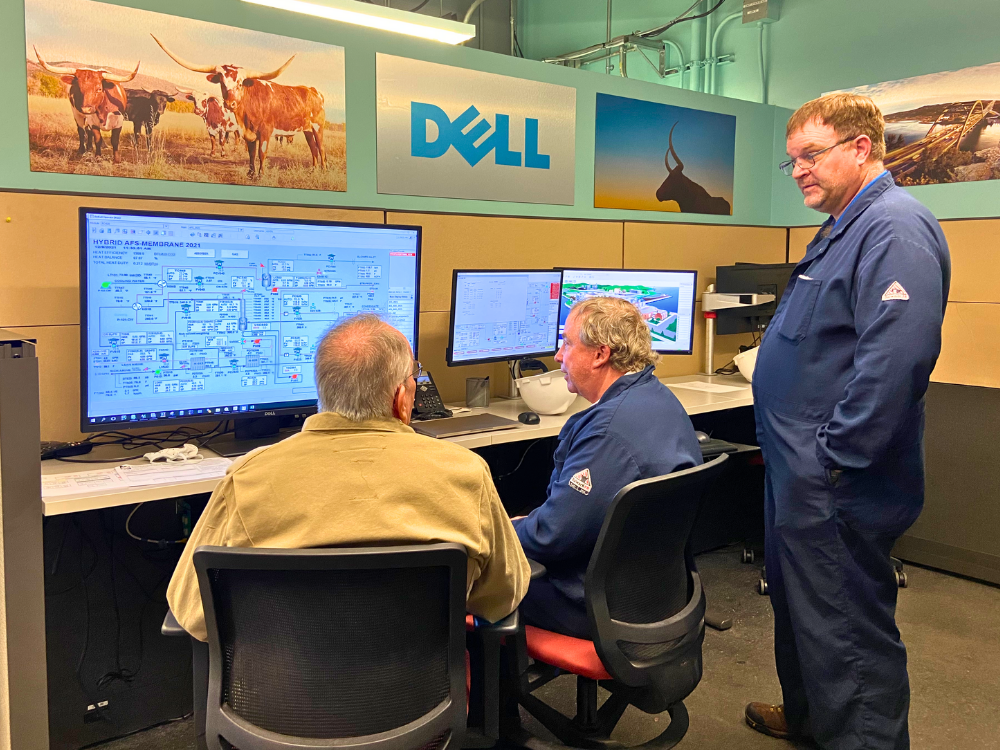

The PSTC also supported workforce development by leveraging government and industrial partnerships for graduate students and post-doc researchers. This tradition continues today with industry and government research partnership agreements managed by Program Head Bruce Eldridge, who took over after Fair leading the PSTC for more than 30 years, and recently retired Technical Manager Frank Seibert — although Frank is still serving as a consultant. Bruce and Frank are also former graduates of the program and alumni of the McKetta Department of Chemical Engineering, both having received their Ph.D.’s in 1986.

In discussing the uniqueness of the facility, Bruce Eldridge said, "To our knowledge, there is no other academic facility like the PSTC in the USA. Between the facility itself and access to world-class researchers and talent, it has a deserved reputation as one-of-a-kind.”

The PSTC conducts work in three major focus areas:

- Separations Technology Development

- Process Optimization, Control, and Safety

- Energy and Environmental Research

It is a win-win. Students and researchers provide real-world data to companies by solving dynamic, relevant problems in a hands-on, controlled environment.

RECENT INVESTMENT AND PARTNERSHIP UPDATES

In February, UT announced a three-year, $8.5 million, partnership with Emerson much of which is aimed at supporting advanced research into artificial intelligence, automation, energy, semiconductors with heavy involvement and leadership from the PSTC. Emerson has been a longstanding, top industrial partner for the PSTC, and it is one of several facilities that will be upgraded through this latest investment.

“This is an exciting new chapter in Emerson’s storied history with The University of Texas at Austin as we build on our vision to accelerate automation and innovation that transforms vital industries,” said Lal Karsanbhai, president and CEO of Emerson.

In 2023, a new Electrified Processes for Industrial eXCellence (EPIXC) was funded through a five-year, $70 million grant from the U.S. Department of Energy and more than $74 million in contributions from industry and other sources. UT Austin researchers received substantial support to investigate the benefits of switching to electric process heating (including steam generation and direct heating technologies). The PSTC will be a key test bed for implementing and validating these new ideas for distillation systems, as one of the most energy intensive operations in the chemical industry.

In 2021, Honeywell entered into a licensing agreement to leverage UT's proprietary advanced solvent technology to offer power, steel, cement, and other industrial plants a new tool to lower emissions generated from combustion flue gases in new or existing units. The solution helps these sectors meet regulatory requirements and sustainability goals. The technology came out of decades of research by Texas ChE Professor Gary Rochelle and his Texas Carbon Management Program that utilizes the PSTC pilot plant and research facilities.

PSTC's FUTURE

The PSTC continues to build momentum and industry interest. With the recent retirement of Technical Manager Frank Seibert and upcoming retirement plans for Program Head Bruce Eldridge, Texas ChE is actively recruiting for a senior faculty position to lead the next exciting chapter for this prized program: Professor of Process Science and Technology in Chemical Engineering.

The posted job application describes a role with "focus on research and teaching in separation technologies. The ideal candidate will be a visionary leader who can bring together collaborative teams from academia and industry, advancing translational research that utilizes the University’s recent multi-million-dollar pilot-scale investments at the Process Science and Technology Center."

As Bruce and Frank are thanked and recognized for their decades of service and contributions to shaping the PSTC into what it is today, the department anticipates a bright future for the center and looks forward to securing its next generation of leadership. If you know of anyone that would be a good candidate for this faculty position, please encourage them to apply.

WRITTEN BY: Steph Lewis